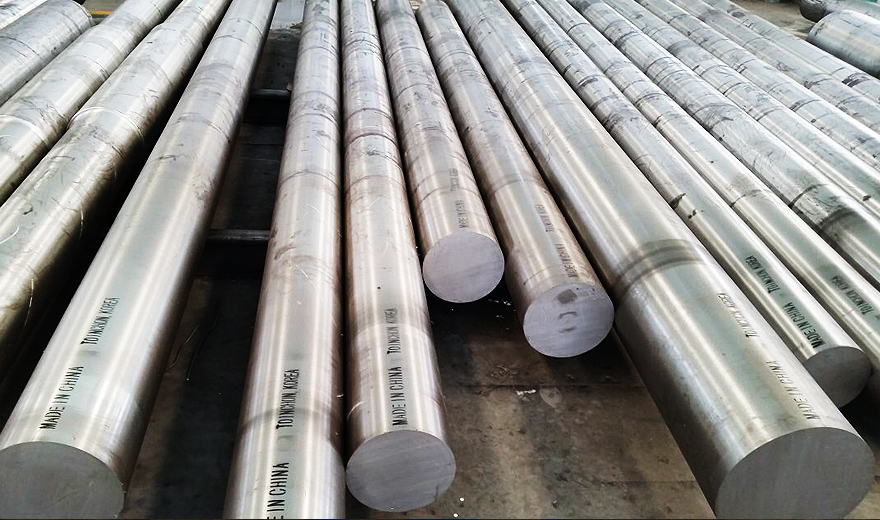

MP35N alloy steel bar is a nickel, chromium, cobalt alloy.

MP 35N is non-magnetic and possesses an ultra-high tensile strength, and provides for good ductility.

MP35N has a maximum 750 degree F temperature capability. In addition, it has excellent corrosion resistance as well to chloride solutions, mineral acids, and in hydrogen sulfides. The ability of MP35N to resist stress-corrosion and crevice corrosion often leads to to its selection as a fastener material, although its uses also include petrochemical equipment, racing engines and submersibles. This alloy is typically work-strengthened and aged to obtain strength levels of 260 to 300 ksi.

melting process

VIM+ESR

Standard & Specifications

- AMS 5844

- SPS-M-663

- GE Aviation S-SPEC-35 AeDMS S-400

Common Applications of MP35N

- Aerospace fasteners

- Tie rods

- Space shuttle structures

- Chemical processing

- Medical

- Cryogenic equipment

- Marine equipment

- Oil & gas

- Food processing