410 Stainless Steel is hardenable, straight-chromium stainless steels which combine superior wear resistance of high carbon alloys with the excellent corrosion resistance of chromium stainless steels. Oil quenching these alloys from temperatures between 1800°F to 1950°F (982-1066°C) produces the highest strength and/or wear resistance as well as corrosion resistance. 410 Stainless Steel is used where strength, hardness, and/or wear resistance must be combined with corrosion resistance.

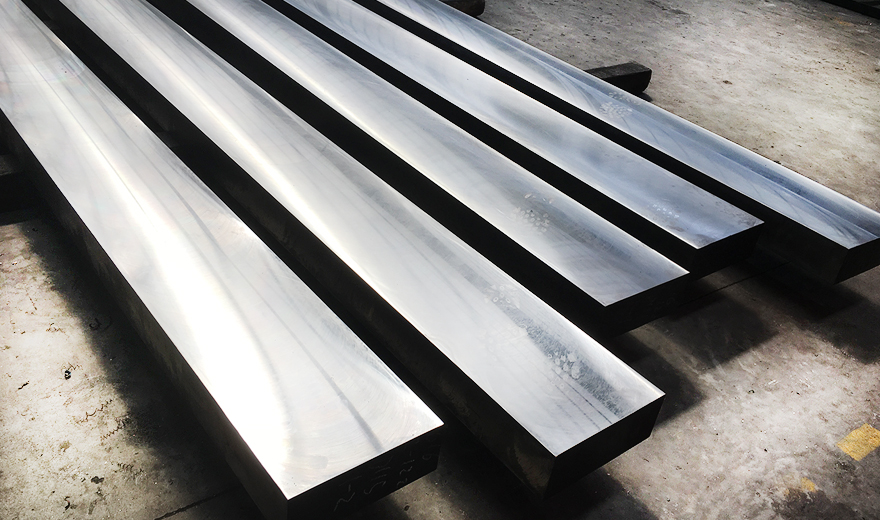

410 Stainless Steel Flat bars

Quick Details

This specification covers hot rolled or forged and heat treated AISI 410 stainless steel suitable for machining into Blade It includes chemical composition, mechanical properties, nondestructive testing, requirements and test methods in order to evalu

Delivery

- Delivery status: Forged 、Q+T 、

- Surface: Milling 、

- Standard: AMS

- Shape: Round, Flat, Square, Hexagon, Plate, Sheet, Other

Inventory Status

| Product type | Products | Dimension | Processes |

|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled |

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded |

Product Details

This specification covers hot rolled or forged and heat treated AISI 410 stainless steel suitable for machining into Blade. It includes chemical composition, mechanical properties, nondestructive testing, requirements and test methods in order to evaluate AISI 410 plates and bars.

410 Stainless Steel is hardenable, straight-chromium stainless steels which combine superior wear resistance of high carbon alloys with the excellent corrosion resistance of chromium stainless steels. Oil quenching these alloys from temperatures between 1800°F to 1950°F (982-1066°C) produces the highest strength and/or wear resistance as well as corrosion resistance. 410 Stainless Steel is used where strength, hardness, and/or wear resistance must be combined with corrosion resistance.

410 Stainless Steel is hardenable, straight-chromium stainless steels which combine superior wear resistance of high carbon alloys with the excellent corrosion resistance of chromium stainless steels. Oil quenching these alloys from temperatures between 1800°F to 1950°F (982-1066°C) produces the highest strength and/or wear resistance as well as corrosion resistance. 410 Stainless Steel is used where strength, hardness, and/or wear resistance must be combined with corrosion resistance.

Related Products

-

410Cb Forging

Gallery project with slider and lightbox.

-

410CB Stainless Steel Forging Flat bar

Gallery project with slider and lightbox.

-

1.4109 / 440A / X70CrMo15 Martensitic Stainless Steel Sheet & Coil

Gallery project with slider and lightbox.

-

X70CrMo1 / 1.4109 Martensitic Stainless Steel Sheet, Strip, Coil

Gallery project with slider and lightbox.

-

S32750 Stainless Steel Seamless Tube Pipe

Gallery project with slider and lightbox.

-

AF1410 High Fracture-Toughness Steel

Gallery project with slider and lightbox.

-

410 Stainless Steel Flat bars

Gallery project with slider and lightbox.

- Previous: PH13-8Mo Forgings

- Next: X12CrNiWTiB16-13, 1.4962 Flat Bar

- Enquiry

- Print this page